Reusable Bulk Plastic Containers: Best Practices for Storage and Handling

Comprehending the Advantages of Bulk Containers in Enhancing Product Handling and Distribution Procedures

Mass containers play a necessary duty in optimizing product handling and distribution. Their layout assists in reliable supply management and minimizes waste, leading to cost financial savings. Furthermore, these containers improve transport effectiveness and improve product security during transit. As industries remain to look for sustainable options, the adaptability of bulk containers ends up being progressively appropriate. Exploring their different advantages discloses understandings that can change operational approaches throughout supply chains. What might these insights require for future methods?

The Function of Bulk Containers in Supply Monitoring

Bulk containers play an essential duty in stock administration by streamlining the storage and transport of large amounts of products. These containers help with efficient company and very easy access to items, thus decreasing the moment spent locating things within storehouses. Their standardized dimensions and designs permit for ideal usage of room, taking full advantage of storage capabilities. In addition, bulk containers improve the precision of inventory monitoring, as they can be easily classified and scanned for stock management systems. The robust nature of these containers protects items from damage during handling and transportation, guaranteeing item integrity. Generally, bulk containers contribute significantly to a more organized, effective, and dependable supply monitoring process, supporting businesses in meeting demand and maintaining operational efficiency.

Cost-Effectiveness of Mass Containers

The cost-effectiveness of mass containers plays a substantial function in contemporary item handling. By decreasing packaging expenses and enhancing transportation logistics, services can accomplish significant financial savings. This financial efficiency not just enhances profitability but also contributes to streamlined operations.

Reduced Product Packaging Prices

Lots of companies discover that using bulk containers notably decreases product packaging prices. By settling items right into larger containers, business can substantially reduce the quantity of packaging material required. This decrease not just reduces the expenses connected with purchasing packaging products however additionally decreases garbage disposal costs. Furthermore, bulk containers simplify the packaging procedure, enabling faster and more reliable packaging operations. Consequently, labor prices connected to taking care of smaller sized packages are also lowered. The toughness of bulk containers frequently leads to less item damages during transit, consequently decreasing the requirement for substitute packaging. Overall, the adoption of bulk containers represents a critical approach to lowering product packaging expenditures while improving functional efficiency

Effective Transport Savings

Considerable savings in transportation prices can be achieved through using mass containers. By making best use of load abilities, mass containers reduce the number of trips needed to transport products, bring about reduced fuel expenses and decreased labor expenses. Their standard measurements facilitate efficient stacking and packing, enhancing room within transportation lorries. Additionally, bulk containers frequently evaluate much less than standard product packaging, permitting for raised hauls without exceeding weight restrictions, further enhancing price performance. The resilience of these containers reduces product damage throughout transportation, lowering returns and losses. Generally, the combination of mass containers in logistics not only improves transportation processes yet additionally considerably adds to cost-effectiveness, making them a crucial part in contemporary supply chain administration.

Reducing Waste With Mass Containers

Mass containers play a necessary function in minimizing waste within item handling systems. By minimizing material waste and advertising reliable resource utilization, these containers add considerably to sustainability efforts. This change towards sustainable packaging solutions not just benefits the setting but additionally improves functional effectiveness.

Reducing Product Waste

Effective monitoring of material waste is a crucial problem in product handling, and making use of bulk containers can play an essential function in resolving this issue. By boosting the volume of products transported at once, mass containers significantly lower the number of deliveries required, consequently decreasing excess packaging waste. Their durable design likewise protects against spillage and damage throughout transportation, further restricting product loss - Bulk Plastic Containers. Furthermore, mass containers are often recyclable, advertising a round economy that motivates sustainability. The standardization of these containers streamlines supply management and minimizes the danger of over-ordering, which can lead to waste. As organizations undertaking for effectiveness, adopting mass containers becomes an efficient method for lowering product waste in various distribution processes

Efficient Resource Usage

While intending for excellent efficiency, many organizations locate that the utilization of bulk containers considerably improves resource administration. These containers help with streamlined operations by reducing the frequency of handling and transport, which subsequently decreases the chance of item loss and damages. By combining materials into bigger systems, business can optimize storage room and lower the requirement for extreme packaging. This strategy not only decreases material costs yet likewise decreases labor connected with taking care of smaller sized bundles. Additionally, mass containers commonly have a longer lifespan contrasted to standard packaging, leading to lower replacement prices and decreased waste. Inevitably, the adoption of bulk containers cultivates a more reliable use sources, contributing to improved operational efficiency and expense savings in the supply chain.

Sustainable Product Packaging Solutions

A significant benefit of using mass containers hinges on their possible to reduce waste in product packaging processes. These containers are designed for reuse, substantially decreasing the demand for single-use packaging products, which add to environmental destruction. By consolidating product storage space and transport, bulk containers enhance space and decrease the total volume of products needed, therefore lowering the carbon impact related to manufacturing and dealing with conventional product packaging. Additionally, their longevity guarantees that they can stand up to numerous journeys, promoting a circular economic situation. As businesses increasingly embrace sustainable methods, the assimilation of bulk containers into supply chains represents a positive method to minimizing waste and improving effectiveness, eventually supporting wider ecological goals and business social obligation campaigns.

Enhancing Transport Effectiveness

Maximizing transportation effectiveness is vital for companies utilizing bulk containers in item handling. Mass containers are created to make best use of area usage throughout transport, allowing for bigger quantities of items to be delivered simultaneously. This reduction in trips equates to reduce transport prices and decreased carbon exhausts, adding to more lasting logistics practices. In addition, the uniformity of mass containers improves filling and unloading procedures, reducing taking care of time and labor expenses. Their tough building additionally provides defense against damage, lowering losses during transportation. Therefore, companies can attain quicker turnaround times, boosting overall supply chain performance. By implementing bulk containers, organizations can greatly enhance their transport logistics, ultimately causing raised profitability and a competitive side in the industry.

Improving Item Safety and Top Quality

Making sure item safety and quality is critical for organizations that make use of mass containers in product handling, as these containers are specifically developed to secure components throughout storage space and transport. The durable building and construction of mass containers shields products from environmental factors such as wetness, contamination, and dirt, which can jeopardize honesty. Additionally, their impermeable seals decrease direct exposure to air, therefore maintaining quality and protecting against spoilage. Moreover, mass containers promote conformity with security policies by offering clear labeling and traceability, which are necessary in various industries, consisting of food and pharmaceuticals. By utilizing mass containers, companies can properly minimize the risk of damages during transportation and straight from the source handling, guaranteeing that items reach their location in prime condition, consequently enhancing consumer contentment and depend on.

Flexibility and Adaptability of Mass Containers

Mass containers use remarkable convenience and flexibility, making them appropriate for a wide variety of sectors and applications. Their layout enables the reliable handling of different products, including powders, liquids, and granules, dealing with industries such as food, drugs, and chemicals. These containers can be conveniently changed or personalized to satisfy certain operational requirements, promoting seamless combination right into existing supply chains. In addition, their stackable nature enhances storage room, enhancing storehouse performance. The capacity to endure various ecological conditions even more prolongs their use throughout varied setups, from manufacturing to transport. This versatility not just improves logistics however also supports companies in meeting rising and fall needs, underscoring the significance of bulk containers in contemporary product managing systems.

Sustainability Advantages of Utilizing Mass Containers

The versatility of bulk containers not only enhances functional performance yet additionally adds considerably to sustainability initiatives across numerous sectors. By minimizing the need for single-use packaging, bulk containers lessen waste generation, resulting in a lower environmental impact. Their multiple-use nature permits business to significantly decrease material usage, while their design advertises reliable transport, decreasing fuel intake and greenhouse gas exhausts. In addition, bulk containers can be easily cleansed and repurposed, additionally prolonging their lifecycle and decreasing the need for brand-new manufacturing sources. This lasting strategy aligns with expanding customer choices for eco-friendly practices, enabling organizations to boost their brand name image while supporting environmental stewardship. In general, the application of bulk containers fosters a much more lasting model for product handling and distribution.

Regularly Asked Inquiries

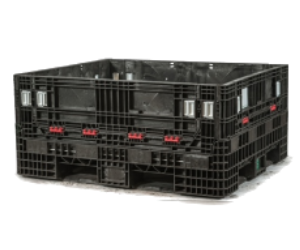

What Products Are Mass Containers Commonly Made From?

Mass containers are normally made from materials such as plastic, steel, timber, or composite products. These options depend upon the container's planned use, sturdiness demands, and the types of items being kept or transferred.

Just How Do Mass Containers Comply With Industry Rules?

Mass containers comply with sector regulations by sticking to security requirements, using accepted materials, and ensuring appropriate labeling. Regular examinations and accreditations additionally guarantee they meet health and wellness, ecological, and transportation guidelines, safeguarding product honesty throughout the supply chain.

Can Bulk Containers Be Personalized for Details Products?

Yes, bulk containers can be personalized for certain items. Manufacturers usually create them to meet one-of-a-kind requirements, ensuring compatibility with numerous materials, enhancing security, and optimizing effectiveness throughout handling and distribution tailored to particular sector requirements.

What Is the Ordinary Life-span of a Bulk Container?

The ordinary life-span internet of a mass container normally varies from 5 to two decades, depending upon the materials used, regularity of use, and maintenance methods. Appropriate treatment can greatly extend its functionality and efficiency.

Exactly how Do I Tidy and Maintain Mass Containers Efficiently?

The resilience of bulk containers often leads to fewer product problems throughout transit, thereby reducing the demand for replacement packaging. Reliable monitoring of material waste is an important problem in find out this here item handling, and using bulk containers can play a critical function in resolving this problem. By settling item storage space and transport, bulk containers maximize room and decrease the overall volume of products called for, therefore lowering the carbon impact associated with manufacturing and disposing of standard packaging. Maximizing transportation effectiveness is important for businesses using mass containers in product handling. Ensuring product safety and quality is critical for companies that utilize bulk containers in item handling, as these containers are specifically made to secure materials during storage space and transportation.